Elevator Stiffener Guide Rail Roll Forming Machine

Basic Info

Model No.: TG-0057

Product Description

The special-shaped galvanized steel Elevator Guide Rail Roll Forming Machine is a professional cold bending equipment designed for different shapes. Because of the particularity and simplicity of the special-shaped steel, the precision of the special-shaped steel is often higher than that of the simple section steel, which requires higher capacity of the Elevator Stiffener Roll Forming Machine. Because of its complex cross-section shape, especially for many special occasions special-shaped steel. The Hollow Guideway Production Line has the characteristics of high precision and good linearity, and can produce hollow guideways of different shapes according to the drawings.

1. Profile Drawing and Products for Reference

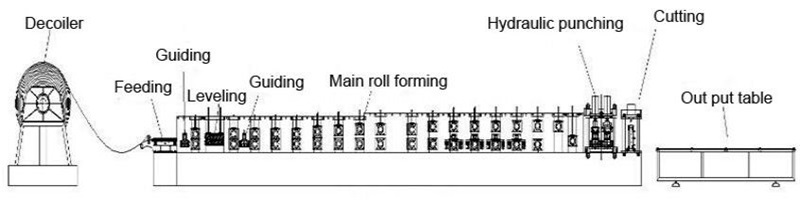

2. Working Flow of Elevator Stiffener Machine

Decoiler---- feeding with guide--- Punching---- Roll forming---- Cutting---- Products collecting

3. Hollow Elevator Guide Rail Machine technical data

| COMPONENT FOR advertising borad forming machine | |||

| Name | Quantity | Units | |

| Decoiler | 1 | Set | |

| Main Machine | Feeding device | 1 | Set |

| Roll forming system | 1 | Set | |

| Cut Equipment | 1 | Set | |

| Hydraulic system | 1 | Set | |

| Electric control system | 1 | Set | |

| Supporter/Automatic Stacker | 1 | Set | |

4. Features and Structure

Ceiling channel roll forming machine

Main-machine interface touch screen for easy operation

Automatic material feeding system

The Elevator Guide Roll Forming Machine can be used for different type of stud and track

Automatic electric control system make production safety ang efficiency

Solid shaft and high quality rollers make the machine working smoothly and endurable

Low noise,low wasting, energy saving and environmental

Elevator Roller Forming Machine has the advantage of beautiful, classical appearance and grace taste.

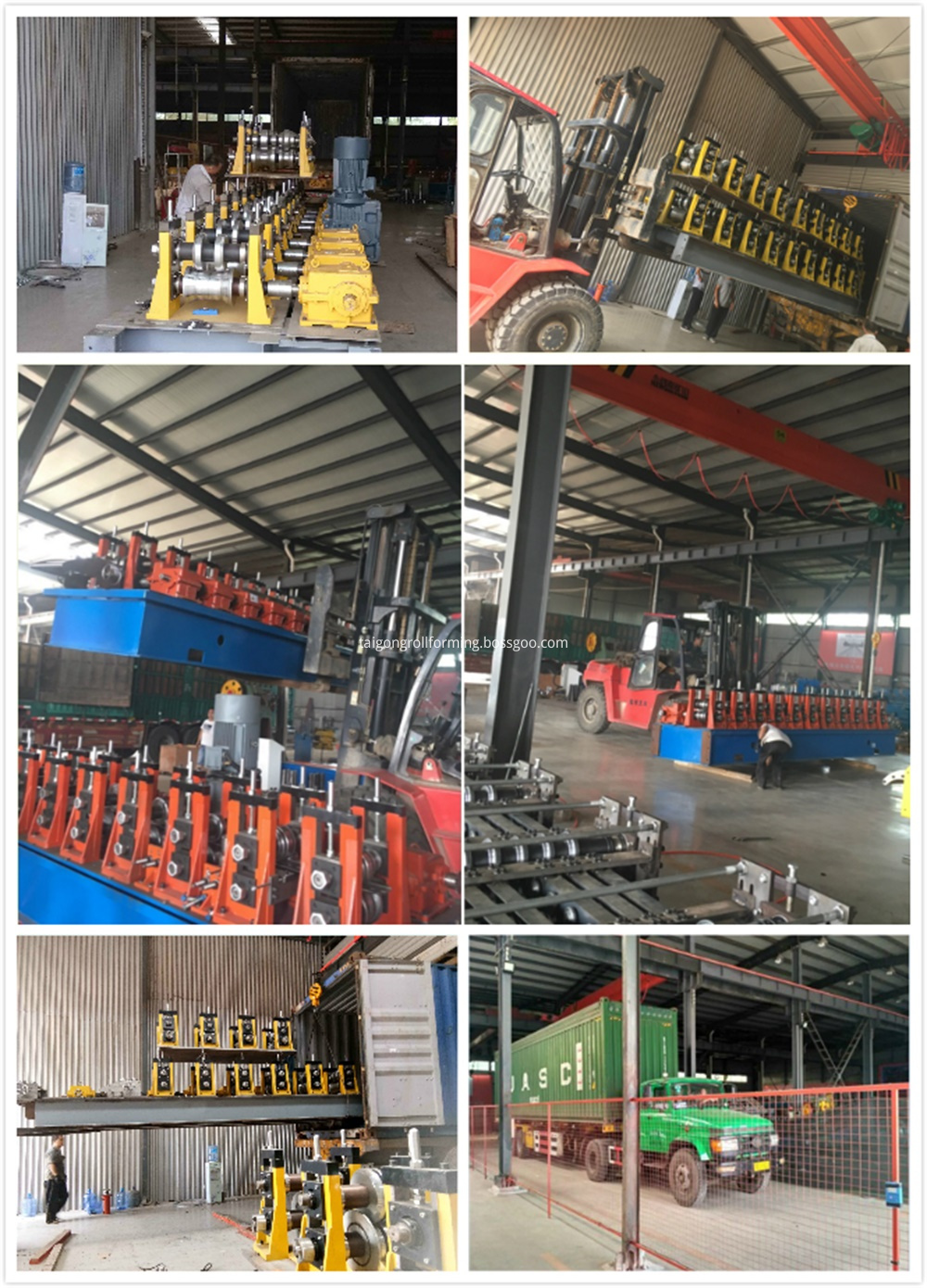

5. Equipment for Reference

6. Scene application

7. Customer

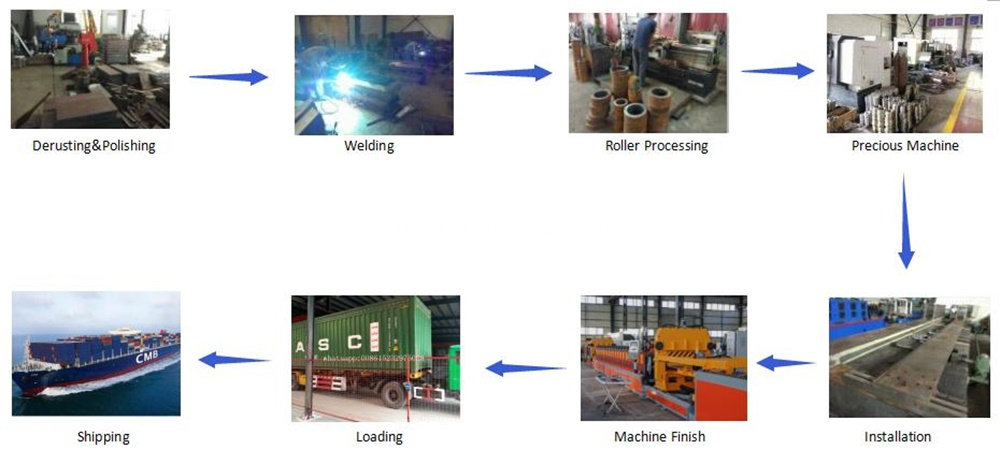

8. Loading

9. Payment terms and after-sale service:

1) FOB Tianjin

2) Payment: 30% T/T deposit, and pay the balance before shipping.

3) Delivery time: 45-50 working days.

4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer.

5) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc.

6) Installation and training:

1. Nude, with waterproof cloth and stow-wood.Imported computer control system packed with waterproof cloth and card board.

2. This producing line is maintained free of charge for 12 months. When the machine is used in China,we will install and debug the machine for free; if it is used at abroad, we will send the professional technician to debug. Buyers should take all the fees for technicians travelling abroad.

3. All the parts in the Elevator Rails Roll Forming Machine is free to maintain all the life, if in 12 months our company bear the cost for exchanged the broken part like the new parts cost and express cost, if more than 12 month, we also free to maintain the broken parts but for send the new parts, the buyer need bear the express cost.

4. When ship the roll forming machine, We will also send one set CD and specification(Chinese and English) to you with the machine, they can teach you how to operater the Elevator Guide Rail Machine

Our main products include Stud Track Roll Forming Machines, Steel Frame Forming Machines, Purlin Roll Forming Machines, Welded Pipe Making Machines, Highway Guardrail Roll Forming Machines, Metal Expanded Mesh Production Lines and so on. If you have any further question of our Cold Roll Forming Machine, please feel free to contact me.

Contact us if you need more details on Elevator Guide Rail Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Hollow Elevator Guide Rail Machine、Hollow Guideway Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Elevator Guide Rail Roll Forming Machine > Elevator Stiffener Roll Forming Machine